Accelerated Carbonation Chamber for concrete Digital

Product Details:

- Humidity 0-95%

- Power Supply 220V AC

- Test Range Effect of CO2 with humidity

- Number of Specimens 4-5

- Power 220V AC Volt (v)

- Weight 275 Kilograms (kg)

- Classification Testing

- Click to View more

Accelerated Carbonation Chamber for concrete Digital Price And Quantity

- 481800.00 - 890000.00 INR/Number

- 1 Number

- 481800 INR/Number

Accelerated Carbonation Chamber for concrete Digital Product Specifications

- Effect of CO2 with humidity

- 220V AC

- 0-95%

- 4-5

- Testing

- Testing

- 275 Kilograms (kg)

- 220V AC Volt (v)

- Effect of CO2 with humidity on Concrete

- White & Brown

- Chamber 600x600x900 Millimeter (mm)

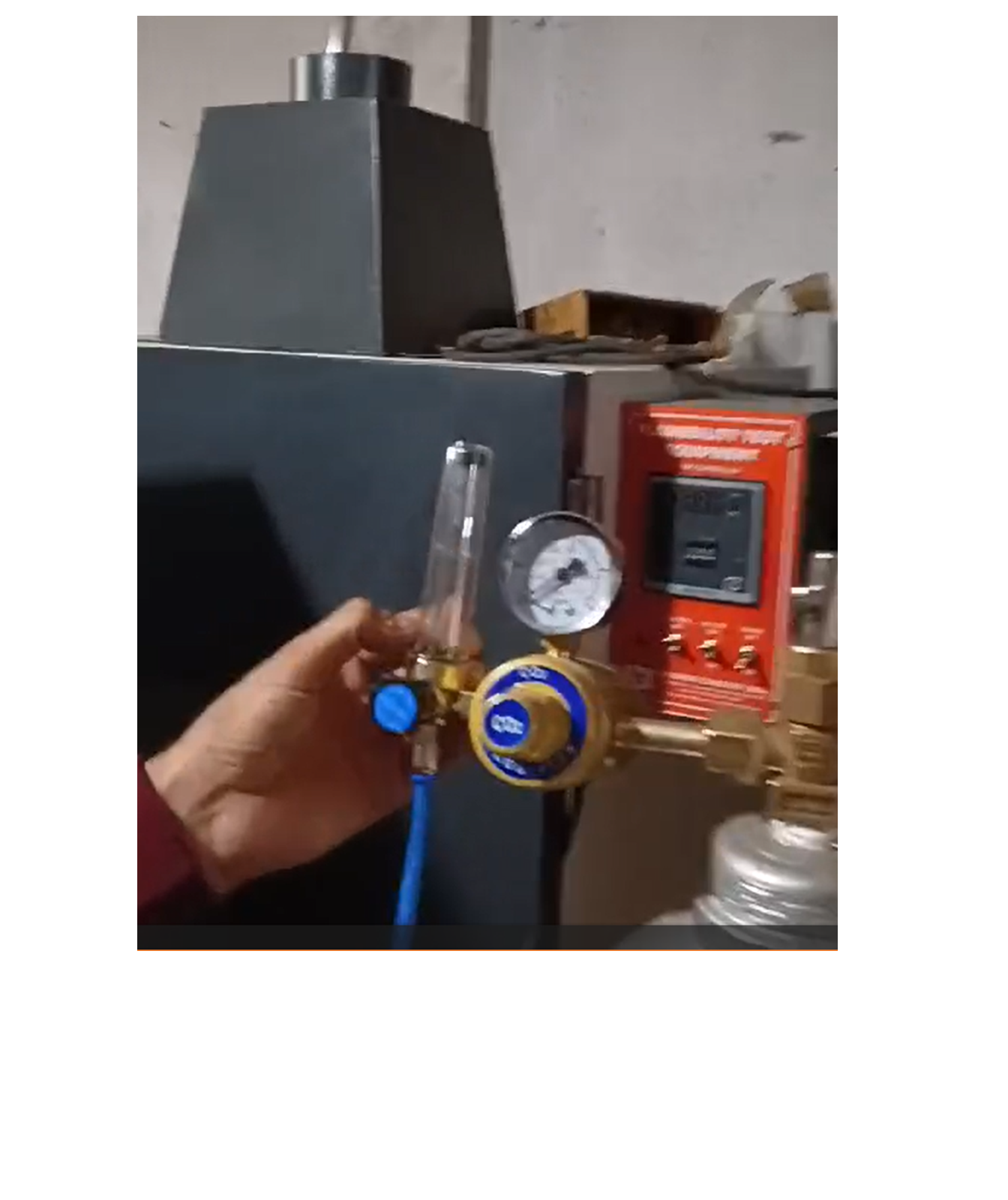

- With CO2 input

- 220V AC Volt (v)

- 340 Ltr/hr

- Accelerated Carbonation Chamber for concrete Digital

- up to 550mm Millimeter (mm)

- 275 Kilograms (kg)

- 60 deg Celsius (oC)

- Metals

Accelerated Carbonation Chamber for concrete Digital Trade Information

- Delhi

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 100 Number Per Year

- 5 Week

- Sample costs shipping and taxes has to be paid by the buyer

- Wooden Packing

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- ALL THE ELECTRICAL ITEMS USED SHALL BE OF STD IP 55GRADE SUITABLE FOR CARBONATION CHAMBER

Product Description

| Accelerated Carbonation Chamber for concrete ï Digital: carbonation chamberfor concretetemp.heating. Temperature: embient to 60 degC, Digital display Humidity : upto 95% , Co2 range : 0-4.5% Dimension:(mm) 600 x 600 x 900 cm capacity : 340 ltr Salient features: 1. double wall construction 2. interior fabricated from high grade stainless steel (s. S. 304). 3. Outer body made of mild steel material duly powder coated 4. Double walled metal door with silicon gasket for air-tight sealing 5. Electrical wiring as per CE compliances 6. Chamber illumination by fluorescent light with door switch. 7. Cord wire duly tested and inspected with stress factor 8. Electric motor located at the back side of unit, protected with safety cover 9. Standard motor of reputed make 10. User friendly chamber door and locking mechanism 11. Impressive outer appearance and high quality air Circulation 12. Temperature is maintained by a quiet running blower circulation air throughout the chamber. 13. Forced air circulated vertically down and re circulated throughout the chamber for uniform temperature and humidity. 14. Humidity created by steam injection method. The boiler tank is fitted with electromagnetic switch for controlling the wet heater from burning off, if water level is inadequate. Float valve provided to control water level in the boiler tank. 15. Long lasting ss tubular heaters used as heating element. The stainless steel fins provided to ensure better heat transfer. 16. Sealed compressor cfc free compressor TRAYS FOR SAMPLES: MANUFACTURED FROM STRONG S.S. TO WITH-STAND HEAVY LOAD AND BETTER AIR CIRCULATION THE DISTANCE BETWEEN TRAYS WILL BE 15-20 CENTIMETERS CONTROL: MICROPROCESSOR BASED DIGITAL AUTO-TUNE PID TEMPERATURE CONTROLLER HUMIDITY: DIRECTLY MEASURED IN % RH BY ELECTRONIC SENSOR. SAFETY FEATURES:

OTHER FEATURES:

|

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Testing Instruments' category

|

RUPSON ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry